EJOT ATF

Fastening Innovation for Battery Thermal Management and EV Systems Integration

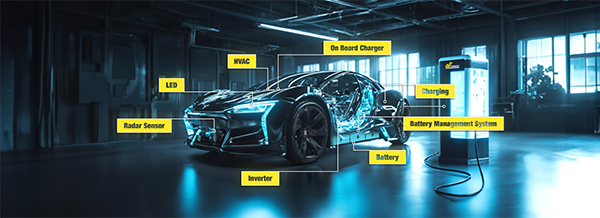

EJOT ATF (Aerospace, Transportation, and Fasteners) is a strategic partnership dedicated to advancing fastening solutions for the evolving needs of electric vehicle (EV) manufacturing. As EV technology accelerates, battery thermal management (BTM), systems integration, and structural reliability demand fastening systems capable of meeting extreme performance, safety, and lightweighting requirements. EJOT ATF delivers precisely this capability—providing fastening technologies that enhance the durability, efficiency, and safety of next-generation EV battery systems.

Fastening Solutions for Battery Integration

EJOT ATF’s fasteners are designed to ensure the secure integration of battery packs into EV platforms, addressing the challenges of joining advanced lightweight materials such as CFRP (carbon fiber reinforced polymers) and EPP (expanded polypropylene). Their solutions provide the structural integrity essential for effective thermal management, enabling battery systems to operate within safe and efficient temperature ranges under real-world conditions.

Advanced Manufacturing Expertise

With deep expertise in cold forming, machining, and assembly, EJOT ATF guarantees precision and durability in every fastening application. This ensures that EV battery housings, enclosures, and thermal interfaces remain robust, even under thermal cycling, vibration, and high-load conditions.

Innovation in Fastening Technology

-

EJOWELD® Friction Welding – Enables secure joining of dissimilar materials such as steel and aluminum in battery enclosures, optimizing lightweight structures while maintaining strength and reliability.

-

EVO PT® Screws – Specialized self-tapping fasteners for thermoplastics, enabling precise, vibration-resistant joints in polymer-based components commonly used in EV battery modules.

Commitment to the Industry

EJOT ATF actively participates in global forums such as the Battery Thermal Management Innovation Summit, engaging directly with OEMs, Tier 1 suppliers, and technology leaders. By collaborating across the value chain, they continue to refine fastening solutions that support innovation in battery thermal management and vehicle electrification.

Stanley Black & Decker

Powering Innovation in Battery Thermal Management

Stanley Black & Decker, through its leading brands such as DEWALT and STANLEY® Engineered Fastening, is shaping the future of electrification with advanced battery and fastening solutions that directly enhance battery thermal management, safety, and performance.

Cell-Level Innovation

DEWALT’s POWERSTACK™ batteries, launched in 2022, utilize pouch cell technology that increases surface area for more efficient heat dissipation compared to cylindrical cells. This allows batteries to run cooler, deliver more power per charge, and extend service life.

Integrated Thermal Management Systems

For high-power applications such as EVs, Stanley Black & Decker develops integrated battery thermal management systems (BTMS). These systems actively monitor and regulate temperatures with intelligent software, cooling and heating mechanisms, and specialized insulating materials such as bio-based Rilsan® powders for inter-cell thermal control.

Fastening & Lightweighting Solutions

Through STANLEY® Engineered Fastening, the company provides joining technologies critical to EV battery enclosures and powertrains. Innovations include:

-

Self-Piercing Rivets (SPR): joining aluminum, steel, plastics, and composites without pre-drilled holes.

-

Lightweight fasteners and Integra™ engineered plastics to reduce vehicle weight while ensuring strength and durability.

-

Advanced grounding studs for safe and reliable electrical flow in EV architectures.

Commitment to Electrification

By combining cell-level breakthroughs, integrated BTMS design, and fastening innovations, Stanley Black & Decker supports OEMs and suppliers worldwide in building lighter, safer, and more efficient EVs. Their technologies help manufacturers overcome the challenges of thermal cycling, lightweighting, and electrification—accelerating the transition to sustainable mobility.

KERAFOL

Advanced Thermal Interface Materials for Battery Systems

KERAFOL® – Keramische Folien GmbH & Co. KG is a leading European manufacturer of technical ceramics, with over 40 years of expertise in ceramic films and thermal interface materials (TIMs). Through its KERATHERM® and KERAMOLD® product lines, KERAFOL delivers critical solutions for battery thermal management (BTM), ensuring safety, performance, and longevity in lithium-ion battery systems.

Thermal Interface Materials for BTM

KERAFOL develops a full range of TIMs tailored to the demands of EV batteries and power electronics, including:

-

Gap Filler Liquids – filling large voids between cells and cooling plates for efficient thermal transfer.

-

Gap Pads & Softtherm® products – compressible, vibration-resistant pads that bridge tolerances and improve contact.

-

Thermally Conductive Films & Adhesives – thin, reliable layers that combine heat dissipation with electrical insulation.

-

KERAMOLD® Granulates – enabling 3D encapsulation of components for optimized cooling and mechanical protection.

Enabling Next-Generation Energy Systems

KERAFOL’s materials are deployed across automotive, power electronics, energy storage, fuel cells, and electrolysis, making the company a vital partner in the transition to electrification and sustainable energy. With proven expertise in ceramics and thermal management, KERAFOL delivers high-performance materials that keep batteries within their safe operating window—between 15°C and 35°C—for maximum safety and efficiency.

EXOES

Immersion Cooling Leader for Safer, Faster, Longer-Lasting Batteries

EXOES, founded in 2009 in France, is a global pioneer in immersion cooling for EV batteries and power electronics. With more than a decade of expertise in fluid-based thermal management, EXOES designs, prototypes, tests, and industrializes advanced cooling systems that set new standards for safety, ultra-fast charging, and battery lifetime extension.

Immersion Cooling Technology

EXOES’ immersion cooling (also called submerged batteries) submerges lithium-ion cells in carefully selected dielectric fluids. This breakthrough solution delivers:

-

Ultra-Fast Charging – full recharge in under 10 minutes.

-

Enhanced Safety – prevents cell-to-cell thermal runaway, avoiding costly recalls and fire risks.

-

Extended Lifetime – up to 3X longer battery life through better temperature homogeneity.

-

Performance Gains – up to 25% more range with fewer cells per pack, lowering weight and cost.

-

Sustainability – reduced carbon footprint versus traditional air- or cold-plate cooling.

Proven Expertise & Validation

EXOES has built deep know-how across the immersion value chain, including:

-

Testing of 30+ dielectric fluids and validation of 7+ immersion architectures.

-

Prototyping of 12+ immersion-cooled modules across all cell formats (cylindrical, prismatic, pouch).

-

In-house simulation, prototyping, and full-scale testing, ensuring rapid, high-quality data trusted by OEMs and Tier-1s.

-

Integrated pack development via its E-MERSIV joint venture, delivering complete immersion-cooled battery packs ready for vehicle integration.

RISE Research Institutes of Sweden

Advancing Battery Safety and Thermal Management

RISE, Sweden’s state-owned, non-profit research institute, plays a leading role in advancing battery safety, testing, and thermal management solutions. With deep expertise in lithium-ion technologies, RISE focuses on preventing and mitigating thermal runaway—one of the most critical risks in battery systems.

Research & Testing Expertise

RISE conducts cutting-edge research into thermal runaway and propagation, supported by specialized calorimeter-based methods to measure heat release, gas emissions, and particle formation. Their unique pressure vessel and abuse testing facilities enable controlled evaluation of thermal runaway events, including UL 9540a certification for battery energy storage systems.

Thermal Management & Safety Solutions

Through multi-physics simulations and full-scale testing, RISE develops predictive models and mitigation strategies for safer batteries, including:

-

Immersion cooling fluids (with partners like Castrol) to suppress runaway risks.

-

Integrated fire extinguishment systems for battery modules and packs.

-

Hybrid cooling and suppression strategies for EV and marine battery safety.

Industry Collaboration & Knowledge Sharing

RISE works closely with OEMs, Tier 1 suppliers, and energy companies—including Scania, Volvo Buses, and Castrol—to co-develop advanced battery safety and thermal management solutions. They also host the Battery Safety Conference, a global forum for sharing insights and innovations in battery safety.

Driving Safer Electrification

By combining world-class testing, simulation, and industry partnerships, RISE provides the expertise and infrastructure needed to improve battery performance, reliability, and safety across electric vehicles, energy storage, and beyond. Their work ensures that next-generation batteries remain safe, stable, and efficient under real-world operating conditions.

NeoGraf Solutions

Flexible Graphite for Advanced Battery Thermal Management

NeoGraf Solutions, LLC, based in Lakewood, Ohio, has been a global leader in graphite materials science for more than 135 years. Today, NeoGraf provides cutting-edge thermal management solutions for EV batteries, energy storage, and advanced electronics through its eGraf® and NeoNxGen® product portfolios.

Thermal Management Solutions

NeoGraf’s flexible graphite products provide lightweight, high-performance alternatives to traditional metals in EV battery packs and beyond:

-

SpreaderShield™ Heat Spreaders – uniformly distribute heat to prevent hot spots and reduce thermal runaway risks.

-

HiTherm™ Thermal Interface Materials (TIMs) – enable efficient heat transfer and electrical insulation between cells and cooling systems.

-

NeoNxGen® Flexible Graphite – a breakthrough single-layer graphite solution with up to 1,100 W/m·K conductivity, offering the performance of multi-layer laminates without added cost or complexity.

Applications Beyond EVs

NeoGraf’s solutions are also critical for grid-scale energy storage, aerospace, drones, and marine batteries, where lightweight, compact, and reliable thermal management is essential.

Expertise & Support

With a global team of engineers, NeoGraf provides custom design, prototyping, and thermal modeling support, helping customers solve their most complex heat management challenges quickly and efficiently.

3M

Materials Science Driving Battery Thermal Management

3M, a global leader in materials science and automotive innovation, provides a comprehensive portfolio of solutions that enhance battery thermal management (BTM), safety, and sustainability for electric vehicles and energy storage systems. With over a century of expertise in adhesives, films, and thermal materials, 3M partners with OEMs worldwide to solve the toughest challenges in eMobility.

Thermal Management & Safety Solutions

3M’s advanced materials support efficient heat transfer, structural reliability, and thermal runaway protection:

-

Thermal Interface Materials (TIMs) – pads, tapes, and epoxies that ensure heat dissipation while maintaining electrical insulation.

-

Battery Enhancement Materials (BEMs) – insulate against external temperatures, extending battery life and range.

-

Thermal Runaway Barriers – flame-resistant and electrically insulating materials, such as the 3M™ Thermal Barrier 5000 Series, designed to slow or prevent propagation between cells.

-

Dielectric Fluids – 3M™ Fluorinert™ and Novec™ fluids enable safe, direct-contact cooling for battery packs and power electronics.

-

Boron Nitride Cooling Fillers & Lightweight Additives – increase polymer conductivity while reducing vehicle weight.

Enabling Next-Generation EV Design

3M solutions address critical challenges in battery assembly, pack-to-chassis integration, sealing, and serviceability. From structural adhesives for cell-to-pack bonding to friction shims that support lighter, downsized fasteners, 3M technologies improve safety, reduce complexity, and enhance manufacturability. Their materials also support repair, reuse, and recycling, helping OEMs design batteries for a sustainable lifecycle.

ScioSense

Early Outgassing Detection for Battery Thermal Safety

ScioSense delivers high-performance environmental and flow sensors for automotive and energy systems. In battery thermal management, ScioSense focuses on early detection of thermal runaway in Li-ion batteries with its BCM1 Battery Condition Monitor—an automotive-grade module that senses cell outgassing well before temperature rise, enabling faster, safer intervention.

What BCM1 Detects & How It Works

-

MOX gas sensing of precursors to runaway: H₂, CO, VOCs, electrolytes.

-

Early warning: detects outgassing ~40 seconds before temperature/voltage sensors respond—supporting the UN EVS 5-minute warning requirement.

-

Automotive integration: LIN or PWM interfaces; optional humidity and pressure sensing; compact, low-power module for EVs and stationary storage.

Benefits for BTM & Safety

-

Prevention & mitigation: flags hazardous events sooner to trigger cooling, isolation, or controlled shutdown.

-

Higher reliability: continuous health monitoring reduces unexpected failures and service events.

-

Performance & life: earlier interventions help maintain optimal temperatures and extend battery lifespan.

Where It Fits

-

EV packs and modules (all architectures) and smart energy storage systems.

-

Complements existing temperature/voltage sensors to form a proactive battery safety layer.

AdvanTech

Embedded Thermal Management for Safer, Smarter Batteries

AdvanTech International Inc. (ATI), founded in 1951, has evolved into a global provider of industrial computing, automation, and embedded systems solutions. With decades of expertise in rugged electronics, Advantech delivers advanced battery thermal management (BTM) technologies that ensure safe, reliable, and long-lasting performance across industrial, medical, and transportation applications.

Custom Thermal Design & Simulation

Advantech’s Embedded Core Group develops tailored thermal solutions, using simulation and flow analysis to optimize heat dissipation in battery-powered systems. Designs balance thermal performance, reliability, cost, and environmental constraints, ensuring stable operation under demanding conditions.

Direct Heat Conduction System (DHCS)

Advantech’s DHCS technology, originally engineered for CPUs, enhances heat transfer and dissipation in battery systems. Its adaptive pressure design prevents damage under vibration while maintaining reliable thermal contact, a benefit for ruggedized and mobile energy applications.

Reliability in Extreme Environments

Advantech tests its systems across wide operating ranges (up to -40°C to +85°C) to guarantee reliability in harsh conditions. For example, medical-grade battery solutions like the POC-BAT-201-62 are engineered for safe operation and extended lifespans within critical thermal thresholds.

Intelligent Software & Monitoring

Advantech integrates thermal protection middleware, enabling direct monitoring of temperature, power, and system parameters. Features like smart fan control, CPU speed regulation, and watchdog timers reduce heat generation and improve overall efficiency.

Battery Testing & System Integration

In the EV and energy storage sectors, Advantech provides industrial PCs and I/O systems for Hardware-in-the-Loop (HiL) testing of Battery Management Systems (BMS). These platforms simulate real-world thermal and electrical conditions, offering a cost-effective way to validate BMS functionality and thermal safety.

Supporting Electrification & Energy Storage

From embedded BTMS for industrial applications to thermal solutions in battery energy storage systems (BESS), Advantech’s technologies address the challenges of heat management, safety, and long-term reliability. Their holistic approach—combining hardware, software, and testing solutions—positions them as a key partner in advancing safe, efficient battery systems.

Carrar

Two-Phase Immersion Cooling for Next-Generation EV Batteries

Carrar, an Israeli battery technology company, is redefining electric vehicle (EV) safety and performance with its proprietary two-phase immersion cooling system. Designed to keep batteries within an optimal temperature range at all times, Carrar’s technology sets new benchmarks for safety, lifespan, and charging speed in EV battery systems.

Innovative Thermal Management Technology

-

Two-Phase Immersion Cooling – leverages latent heat: coolant absorbs heat by evaporating and releases it during condensation, ensuring rapid and efficient dissipation.

-

Patented Nucleation Material – enhances boiling efficiency, providing stable and uniform cooling across every cell.

-

Dynamic Thermal Control – adjusts cooling in response to charging, driving, and environmental conditions, maintaining cell temperatures between 25°C and 27°C.

Benefits for EV Batteries

-

Extended Lifetime – up to 3X longer battery life compared to conventional systems.

-

Ultrafast Charging – supports full charges within minutes, without heat-induced degradation.

-

Improved Safety – mitigates thermal runaway risks by preventing hot spots and temperature spikes.

-

Higher Efficiency – enables up to 10% fewer cells per pack while still increasing driving range by ~7%.

-

Lower Total Cost of Ownership – fewer replacements, greater efficiency, and enhanced sustainability.

Broad Applications & Partnerships

Carrar’s thermal management is chemistry-agnostic, compatible with LFP, NMC, NCA, and other pack designs. Beyond batteries, Carrar also applies its cooling solutions to power electronics and vehicle control units, enabling higher-density, safer designs. The company collaborates with leading OEMs, Tier 1 suppliers, and partners like Gentherm to bring its breakthrough technology to market.

Huber Advanced Materials

Engineered Materials for Battery Safety and Thermal Management

Huber Advanced Materials, a division of Huber Engineered Materials, delivers specialty inorganic materials that play a critical role in the performance, safety, and reliability of lithium-ion batteries. With expertise in thermally conductive fillers, fire-retardant additives, and separator coatings, Huber provides the building blocks for safer, longer-lasting, and more efficient EV batteries.

Thermal Management Solutions

Huber’s portfolio of magnesium hydroxide (MDH), aluminum hydroxide (ATH), and calcined alumina fillers enables high thermal conductivity in polymer composites and TIMs. These materials can reach up to 90% loading by weight, ensuring effective heat dissipation while balancing cost, processability, and mechanical properties. Products such as Martinal® TM, Magnifin® TM, and Martoxid® TM are designed specifically for EV thermal management applications.

Safety and Reliability Enhancements

-

Thermal Interface Materials (TIMs): ATH-based TIMs engineered for gap fillers in EV modules, improving heat transfer between cells and cooling plates.

-

Fire Retardant Additives: Halogen-free solutions that enhance polymer safety in battery enclosures, meeting global standards like UL-94/V0 and ECE R100.

-

Separator & Cathode Coatings: Fine alumina-based coatings increase separator safety and mechanical strength, while aluminum-doped cathodes extend cycle life of nickel-rich chemistries (NMC/NCA).

Benefits for EV Batteries

-

Improved Safety – prevents overheating and thermal runaway with flame-retardant and insulating additives.

-

Enhanced Reliability – consistent heat dissipation ensures stable performance under high loads.

-

Extended Lifespan – optimized thermal conditions reduce degradation over time.

-

Cost-Effective Solutions – engineered fillers balance high performance with scalable manufacturability.

Fraunhofer Institute for Silicon Technology

Data-Driven Thermal Intelligence for Safer, Faster-Charging Batteries

Fraunhofer Institute for Silicon Technology (ISIT) in Itzehoe is one of Europe’s most advanced centers for microelectronics and microsystems. With a 3,000 m² industrial-scale cleanroom and 160 scientists, ISIT co-develops sensors, power electronics, and control systems with industry—capabilities it now applies to intelligent battery thermal management (BTM).

Intelligent Thermal Management

-

Data-driven modeling & control: in-situ data feeds high-fidelity thermal models to enable real-time, active thermal control at cell level.

-

Optimized fast charging: dynamic control maintains safe temperature limits, shortening charge times beyond conservative strategies while protecting the cell.

-

Hybrid systems expertise: projects like HYBAT combine advanced operation strategies with innovative thermal designs.

Integrated Sensing & Safety

-

Embedded sensing of electrode potentials, temperature, pressure, and volume expansion detects risks early (e.g., Li-plating) to prevent thermal runaway.

-

Safety testing & analysis: destructive and non-destructive methods to study propagation, validate countermeasures, and harden packs against abuse.

From Cell to System

-

System design support: cell characterization, state estimation, thermal architecture, and cost-effective controller development for new or retrofit packs.

-

Applications: electric forklifts, grid-connected BESS, safety-critical systems (e.g., submarines), heavy-duty EVs, and fast-charging robotics.

BURGER GROUP

High-Torque Actuators for Smart Battery Thermal Management

BURGER GROUP is a leading system partner in customer-specific drive technology, developing and manufacturing electromechanical solutions for automotive thermal management. Burger Group supplies high-torque, compact valve actuators that precisely regulate coolant and refrigerant flow in battery thermal management systems (BTMS).

Purpose-Built Actuators for BTMS

-

Product family: HTDC, HTBL, EVO, and FS (Fail-Safe) actuators engineered for modern multi-port thermal modules (5–9+ ports).

-

High torque density: reliable actuation of larger rotating valve bodies for complex coolant/refrigerant routing to batteries, power electronics, and HVAC.

-

Passive safety: FS actuator includes spring-return to a safe position on power loss for emergency cooling strategies.

Engineered for Your Architecture

-

Customization: selectable DC motors, gearbox materials (e.g., PEEK for extended life, stainless steel, aluminum), and housing geometry for drop-in integration.

-

Sensing & robustness: options such as Hall-effect position sensing (≈ ±1° accuracy); designs optimized without PTFE seals to meet emerging standards.

-

Production scalability: from high-volume platforms to bespoke runs for trucks, buses, and off-road vehicles.

Impact on Battery Safety, Performance & Life

-

Safety: precise flow control and fail-safe behavior support mitigation of thermal runaway propagation.

-

Performance: maintains pack temperatures in the ~15–35 °C window for stable power and faster charging.

-

Longevity: reduces thermal stress and cycling, extending battery service life.

Saleri TMS Competence Center

Integrated Thermal Management for Next-Gen BEVs

Saleri’s TMS Competence Center engineers vehicle-level thermal architectures that keep BEV batteries in the optimal ~15–35 °C window for safety, range, fast charging, and lifetime. Saleri supports OEMs with end-to-end system definition, component selection, and calibration for integrated BTMS across next-generation platforms.

Integrated Systems & Key Products

-

ITMM – Integrated Thermal Management Module

A compact hub that interconnects all heat users (battery, e-axle, power electronics, cabin). High integration reduces weight, package volume, and coolant, extending range and simplifying vehicle installation. Benefits include more clearance, better serviceability (one location), and a streamlined final assembly. -

E-Pumps Range (12 V / 24 V, 30–600 W)

Customizable interfaces for OEM BTMS; compatible with water-glycol and alternative fluids to deliver reliable coolant distribution and precise temperature control. -

Mechanical & Switchable Water Pumps

Proven primary circulation with strategies to minimize CO₂; switchable variants enable optimized temperature control across duty cycles. -

Electromechanical Pumps (Dual-Drive)

Instant switching between mechanical and electric modes, energy savings during warm-up, and zero-flow capability when cooling isn’t needed.

Why It Matters for BEVs

-

Safety: Stable cell temperatures help mitigate thermal-runaway risk.

-

Performance: Coordinated cooling supports higher sustained power and faster charging.

-

Longevity & Efficiency: Lower thermal stress extends battery life while integrated hardware cuts mass, fluids, and complexity.

Saleri couples system-level thermal design with highly integrated modules and pump technologies to meet the automotive industry’s evolving needs—boosting safety, autonomy, and total vehicle efficiency in electric mobility.

CIDETEC

Direct-Liquid Cooling & Data-Driven Control for Safer, Longer-Lasting EV Batteries

CIDETEC is a leading applied-research organization comprising three institutes—Energy Storage, Surface Engineering, and Nanomedicine—with the Energy Storage institute focused on taking battery innovation from materials to validated packs.

What CIDETEC Delivers for BTM

-

Partial Direct Liquid Cooling (patented): targeted cell-surface cooling that provides precise thermal response with less fluid and volume than immersion systems—improving safety, fast-charge capability, and packaging efficiency.

-

Direct Liquid Cooling for EVs: dielectric-fluid designs that remove thermal barriers, enhance runaway mitigation, and extend cycle life.

-

Data-Driven Thermal Modeling & Control: high-fidelity models and real-time control to shorten charge times safely and keep cells within optimal limits.

-

Open & Advanced Tools: cideMOD (open-source) and Proteo (advanced, web-based) to study thermal behavior, degradation, and to optimize pack design and operation.

Safety & Intelligence

-

Early-risk algorithms: detection of thermal risk events (TRA) and Li-plating, validated by in-house TRA testing.

-

Integrated sensing: electrode potentials, temperature, pressure, and swelling for in-situ state estimation and safer fast charging.

From Lab to Road

-

End-to-end capability: materials validation, pilot manufacture, pack engineering, and battery testing (cycling, abuse, thermal).

-

System integration: module/pack design, cloud-enabled BTMS control, and support for retrofit or new platforms across EVs, BESS, forklifts, robotics, and heavy-duty applications.

XING Mobility

Immersion-Cooled Batteries for Safer, Faster, Longer-Lasting Power

XING Mobility pioneers immersion cooling for EV and energy-storage batteries. Its IMMERSIO™ architecture submerges cells in a dielectric fluid for ultra-uniform, rapid heat removal—boosting performance and life while actively suppressing thermal runaway.

What XING Delivers for BTM

-

Direct immersion cooling: cell-level heat extraction with tight uniformity (fluctuations ~3%) and >30% higher cooling efficiency vs. indirect systems.

-

Active runaway suppression: cools cells below 100 °C in <30 s to prevent propagation—even under severe abuse (e.g., multi-nail penetration).

-

CTP/CTC designs: IMMERSIO™ cell-to-pack and chassis-integrated prototypes for higher energy density (CTC >35%).

-

Integrated BMS: XING’s BMS is tuned to immersion thermals for precise fast-charge and protection strategies.

Products, Proof & Scale

-

IMMERSIO™ series (e.g., XM25, XM28, CTP models) and the XBE1000 1 MWh ESS cabinet.

-

Certified & validated: tested to UN38.3, ECE R100, IEC 62619; production facility in Taiwan.

-

Real-world gains: faster charging (≈16–18% reduction in charge/discharge time), extended life (up to ~20% and up to 2× vs. air-cooled), and improved warm-up performance.

XING Mobility’s immersion-cooled IMMERSIO™ batteries combine class-leading safety, fast charging, and high energy density—a turnkey path to robust electrification in the most demanding use cases.

Siemens Digital Industries Software

Simcenter & Digital Twins for Battery Thermal Excellence

Siemens Digital Industries Software helps organizations transform product development with the Siemens Xcelerator platform. For battery thermal management in EVs, Siemens delivers an end-to-end toolchain—centered on Simcenter—to model, predict, and control pack temperatures from cell to vehicle.

What Siemens Delivers for BTM

-

Digital Twin of the Battery & Vehicle: virtual prototypes that connect electrochemistry, heat generation, cooling hardware, and controls to de-risk designs before hardware exists.

-

CFD & Conjugate Heat Transfer (CHT): Simcenter STAR-CCM+ evaluates airflow/liquid cooling, cold plates, manifolds, and temperature gradients; identifies hot spots and pressure drops.

-

Electrochemistry Coupling: Simcenter Battery Design Studio provides cell/stack models and parameters to drive physically realistic thermal simulations.

-

Thermal Runaway Analysis: dedicated Thermal Runaway Heat Release Model and propagation studies to design barriers, vents, and mitigation strategies.

-

BMS & Controls: software tools to implement and validate thermal strategies (coolant flow, fans, heaters) that keep cells in safe operating ranges across duty cycles and climates.

Use Cases & Applications

-

Optimize cooling architectures (air vs. liquid, plate topology, coolant routing) for fast charging and track/high-load scenarios.

-

Multi-scale BTM from cell → module → pack → vehicle, including cabin comfort co-simulation.

-

Aging-aware charging control to limit degradation and improve charge times.

-

Race and high-performance programs: accelerate iteration, reduce track tests with validated virtual campaigns.

Outcomes

-

Performance & Life: tighter thermal control improves power capability and extends lifespan.

-

Safety: design-for-mitigation of thermal runaway and propagation.

-

Speed & Cost: fewer physical prototypes, faster convergence, and lower development spend.

Kurybees

Cell-to-System Modeling for Intelligent Battery Thermal Management

Kurybees accelerates battery innovation with advanced physics-based and data-driven modeling. Focused on thermal behavior from cell to pack, Kurybees helps OEMs and suppliers design BTMS that maximize performance, safety, and durability—while cutting development time and risk.

What Kurybees Delivers for BTM

-

Cell-level heat source decoupling – quantify ohmic, charge-transfer/kinetic, and entropy heating to pinpoint where and when heat is generated across chemistries.

-

Multi-physics digital twins – coupled electrochemistry–thermal–mechanical–aging models for precise temperature prediction, gradient minimization, and hotspot avoidance.

-

Control-oriented models – reduced-order and real-time models for BMS/BTMS to enable fast charging within safe limits and adaptive thermal control.

-

Degradation & safety analytics – algorithms and test methods for early risk identification (e.g., Li-plating indicators), supporting strategies to prevent thermal runaway.

Services Across the Product Lifecycle

-

Model development & parameter databases (Matlab/Simulink, COMSOL Multiphysics, Siemens Battery Design Studio); high-performance computations on Kurybees servers.

-

Design & sizing – system-level trade-offs, fast-charge profile generation, and pack architecture choices guided by thermal KPIs.

-

Testing & characterization – electrode/cell/module/pack test procedure design, DoE, bench programming (Biologic, Neware, Digatron, Kratzer), and ante/post-mortem analysis.

-

R&D and sourcing support – technology roadmaps/TRL, regulatory tracking, supplier/RFQ support, and project/training services.

Impact for Battery Programs

-

Safety: earlier detection + mitigation pathways to reduce thermal propagation risk.

-

Performance: tighter thermal control for higher power and faster charging.

-

Longevity: thermal-aware operation that slows aging and extends warranty life.

-

Efficiency: fewer prototypes and quicker convergence using validated models.

NIO

All-Climate Battery Thermal Management with Cloud-Connected Intelligence

NIO is a pioneer in premium smart EVs, coupling all-climate thermal management with a bi-directional, cloud-connected BMS to maximize range, fast-charge performance, and battery life—while enhancing safety through thermal-propagation prevention.

What NIO Delivers for BTM

-

Active + Passive Cooling: liquid cooling for high loads/fast charging; insulation and low-conductivity materials to minimize cold-weather losses.

-

Radiant Thermal Compensation Heater: uniformly preheats cells for cold climates to keep packs in the optimal window (≈ 15–35 °C).

-

Cloud BMS (bi-directional): real-time, over-the-air parameter tuning and diagnostics for precise thermal control across climates, duty cycles, and pack conditions.

-

Thermal Propagation Prevention: architecture and controls designed to inhibit cell-to-cell spread in abuse events.

Pack Architecture & Technology

-

Cell-to-Pack (CTP): higher space utilization and energy density with simplified pack structure.

-

Dual-Chemistry Packs: blends ternary Li-ion with LFP to improve low-temperature performance while optimizing cost, safety, and range.

Battery Swapping Integration

-

Power Swap stations: rapid, automated pack exchange in minutes; station-level cooling/heating maintains safe charging conditions across mixed pack states.

Benefits for Drivers & Fleets

-

Range & Performance: tighter temperature control supports sustained power and efficient fast charging.

-

Longevity: reduced thermal gradients and adaptive control slow degradation.

-

Safety: early detection + mitigation strategies reduce propagation risk in abnormal events.

NIO’s combination of CTP design, dual-chemistry innovation, and cloud-orchestrated thermal control delivers consistent performance, safety, and durability—from sub-zero winters to peak-load summers—and scales seamlessly with its battery-swapping ecosystem.

Rubitherm Technologies

Phase-Change Materials for Stable, Safer Battery Temperatures

Rubitherm Technologies is a global leader in phase change materials (PCMs) that deliver passive thermal control for EV and energy-storage batteries. By absorbing excess heat during charge/discharge and releasing it later, Rubitherm PCMs stabilize pack temperatures, cut gradients, and help prevent heat-driven degradation.

What Rubitherm Delivers for BTM

-

Tailored PCM portfolios (RT & SP series): precise melting points from −20°C to 100°C for cell/module needs across climates; high latent heat for compact, effective thermal buffering.

-

Safety-oriented options: SP-line (salt-based, low-flammability) delivers high volumetric storage where safety is critical.

-

Form factors & integration: bulk materials and carrier combinations (fibres, granulates, powders) for easy integration around cells, busbars, and enclosures.

-

Validated performance: demonstrated battery temperature reduction in demanding use cases (e.g., Formula Student with RT44HC) and in EV range-extension projects such as the EU-funded QUIET initiative.

Benefits for EV Packs & BESS

-

Temperature stability: narrows peak temps and minimizes gradients, improving uniformity and fast-charge reliability.

-

Longevity & efficiency: reduced thermal stress slows aging, preserves capacity, and can extend driving range by easing active cooling loads.

-

Fail-safe simplicity: passive operation adds resilience, complements liquid/air systems, and supports thermal propagation risk mitigation strategies.

Rubitherm’s custom-tuned PCMs give OEMs and integrators a lightweight, passive layer of defense that smooths thermal spikes, boosts safety, and extends battery life—and integrates cleanly alongside active BTMS hardware.

Eberspächer Group

Integrated Thermal & Connectivity Solutions for EV Battery and Cabin

Eberspächer Group is a global Tier-1 partner delivering integrated thermal management systems for electric and hybrid vehicles. Its architectures manage battery packs and cabin climate as one system, boosting range, fast-charge performance, safety, and comfort across passenger, commercial, and special-purpose fleets.

What Eberspächer Delivers for BTM

-

System Integration: vehicle-level coordination of battery, e-motor, power electronics, and HVAC to keep packs in the ~20–40°C window.

-

Heat Pumps (incl. Dualtronic): high-efficiency reversible heating/cooling to minimize energy draw in cold and hot climates.

-

PTC Heaters: rapid, dependable supplemental heat for battery and cabin in low-temperature operation.

-

Modular Platforms: scalable kits—with or without heat pump—to suit regions, trims, and duty cycles.

-

Battery Management Systems (BMS): LV/HV BMS for monitoring, protection, and optimized thermal-charging strategies.

Digital & Fleet Connectivity

-

Smart connectivity & data services: remote status, alarms, and diagnostics; multi-vehicle networking via a digital platform for uptime and preventive maintenance.

-

Pre-heaters & AC components: fuel-operated and electric water/air heaters integrated into cooling circuits; HVAC modules to stabilize comfort and operator concentration.

Benefits for EV Programs

-

Extended range & efficiency: lower HVAC load and precise pack temperature control.

-

Battery longevity: reduced thermal stress slows aging and supports consistent performance.

-

Safety & reliability: BMS-driven diagnostics and thermal control mitigate propagation risk and support safe fast charging.

-

Simplified integration: modular hardware and software shorten OEM time-to-market.

Eberspächer unites heat pumps, PTC heaters, modular BTMS, BMS, and connected services into a cohesive thermal ecosystem—delivering range, longevity, safety, and fleet-ready uptime for electrified vehicles.

SynErgy Thermal Management

Vehicle-Integrated Thermal Management for Efficient, Long-Life EV Batteries

SynErgy Thermal Management designs vehicle-level thermal systems that treat the battery, cabin, e-powertrain, and controls as one coordinated whole. By tightly integrating BTMS with the Vehicle Control Unit (VCU) and energy management, SynErgy maximizes range, enables reliable fast charging, and extends battery life.

What SynErgy Delivers for BTM

-

System integration with the VCU: coordinated setpoints for battery, HVAC, and power electronics to minimize consumption while keeping cells in the ~15–35 °C window.

-

Model-Predictive Control (MPC): real-time, control-oriented models to optimize cooling/heating during fast charge and high load, balancing charge time, safety, and durability.

-

Advanced materials & hybrids: phase-change materials (PCMs) and nano-enhanced PCMs, plus hybrid active/passive concepts (liquid cooling + PCMs/heat pipes) to cut gradients and peak loads.

-

Field Synergy Analysis: flow-field and heat-transfer optimization inside modules and packs to improve uniformity and reduce hotspots.

Modeling, Simulation & Validation

-

Multi-physics digital twins (electrochemistry–thermal–mechanical–aging) for cell→module→pack→vehicle.

-

Toolchain: Dymola with XRG Human Comfort Library and Modelon Air Conditioning Library, combined with SynErgy’s in-house models for refrigerant cycles, HVAC, and BTMS.

-

From targets to tests: derive subsystem requirements from vehicle KPIs; support component, system, and vehicle validation with DoE-based test plans.

Impact for EV Programs

-

Efficiency & Range: lower thermal energy draw through predictive, vehicle-aware control.

-

Fast Charging, Safely: MPC limits plating/over-temp while meeting charge-time goals.

-

Longevity & Reliability: minimized gradients and smarter thermal trajectories slow aging and reduce warranty risk.

-

Scalable Architecture: configurable for passenger cars, trucks, and specialty vehicles.

SynErgy brings cell-physics insight into system-level control, delivering holistic, predictive thermal management that boosts range, safety, and lifespan—and accelerates OEM time-to-market with validated, model-driven design.

X2F

Thermally Conductive Molding for Cooler, More Reliable Battery Systems

X2F is commercializing a new class of low-pressure, Controlled Viscosity Molding (CVM) that overmolds delicate electronics and complex geometries with highly filled, thermally conductive polymers—creating efficient heat pathways right where battery systems need them most. Using a patented pulse-pack approach with closed-loop viscosity control, sensors, and data capture, X2F enables heat-spreading encapsulation without damaging sensitive components.

What X2F Delivers for BTM

-

Proven temperature drop: thermally conductive CVM encapsulation has shown ~25–30% temperature reduction in battery management systems—supporting faster charging, higher energy density, and longer life.

-

Reliability by design: encapsulation addresses the four major electronics risks—dust, humidity, vibration, and heat—while eliminating PCB hot spots that can throttle charge/discharge performance.

-

Better than potting/coating: replaces labor-intensive conformal coating/potting with high-conductivity molding that moves heat out quickly; optional “skylining” uses minimal material for lighter parts.

-

Rapid, scalable builds: CVM pairs with 3D-printed tooling for quick prototypes and lower launch costs, then scales to production with consistent thermal performance.

-

Sustainability: the CVM process typically uses 50–90% less manufacturing energy, contributing to greener battery and electronics supply chains.

Why it matters

Nearly 55% of component failures are heat-related; CVM places thermally conductive pathways exactly where heat is generated, reducing cycling stress, preventing hot spots, and improving safety and uptime for BMS, packs, and power electronics.

Greenectra OÜ

Coaching, Consulting & Teams for Battery Thermal Management

Greenectra OÜ empowers companies to design, validate, and scale battery thermal management systems (BTMS). Led by CEO Dr. Frank Richter, Greenectra bridges cutting-edge research and industrial practice through expert consulting, hands-on training, and talent solutions—so programs avoid common pitfalls, predict aging, and deliver safer, longer-lasting batteries.

What Greenectra Delivers for BTM

-

Advisory & Design Reviews: pack architecture, active/passive cooling (liquid, air, PCMs), thermal interface selection, and energy-efficient control to keep cells in the ~20–40 °C window.

-

Thermal Risk & Safety: analysis of thermal runaway & propagation in large packs/BESS; detection strategies, fire-suppression concepts, and test plans.

-

Modeling & Aging Insights: cell-level heat source decoupling (ohmic, kinetic, entropy), gradient minimization, and predictive aging models to set fast-charge and durability limits.

-

Testing & Validation: DoE-based procedures for cells/modules/packs; instrumentation, data analysis, and acceptance criteria.

-

People & Capability Building: BattXcel training programs, tailored courses/webinars, and recruiting support to build high-performing BTMS teams.

-

Partnerships & Reach: collaboration with FME BATTERY (education support) and initiatives across Africa & the Middle East.

Impact for Battery Programs

-

Safety & Reliability: earlier risk detection and robust mitigation reduce recall risk.

-

Performance & Life: tighter temperature control improves efficiency and extends service life.

-

Speed & Cost: clearer requirements, better tests, and stronger teams accelerate time-to-market.

Whitemark Technology

Ultra-Fast Charging via Immersion Thermal Management

Whitemark Technology is an innovation lab advancing patented immersion cooling & heating for high-performance, ultra-fast-charging batteries. By submerging cells in a non-toxic cooling liquid and controlling pole and cell temperatures precisely, Whitemark reduces degradation, extends life, and enables rapid charge rates for demanding, off-highway applications.

What Whitemark Delivers for BTM

-

Immersion cooling & active heating: uniform temperature control (target ~20–25 °C) for stable performance in all climates.

-

Ultra-fast charging: designed to achieve 20–80% in ≈12 minutes while maintaining cell health.

-

Modular architecture: immersion-cooled battery modules with flexible configurations and simplified service.

-

Integrated BMU: precise thermal supervision, variable charge/discharge voltages, CCS fast-charge compatibility, and safety features aligned with EN ISO 13849.

Products & Use Cases

-

Kea Boost 50: combines immersion-enabled ultra-fast charging, telemetric fleet unit, and CCS compatibility—driving more uptime, less downtime.

-

Target sectors: forklift trucks, construction machinery, ships, and other heavy-duty platforms needing rapid turnaround and high reliability.

How Programs Benefit

-

Longer life, less degradation: immersion keeps cells in their sweet spot—claims of up to ~3× reduction in degradation under proper use.

-

Safety by design: liquid immersion and BMU safeguards mitigate hot spots and thermal events.

-

OEM-ready collaboration: Whitemark operates as a consortium of specialists—co-developing custom solutions with OEMs/OESs and scaling with trusted engineering partners.

Battery-Kutter GmbH & Co. KG

Custom Packs & BMS with Built-In Thermal Intelligence

Battery-Kutter is a DIN EN ISO 9001/14001 certified, second-generation family business (est. 1989) specializing in the production and distribution of batteries and custom battery packs. With own brands (SUN Battery, SSB Battery, LiBrick), one of Germany’s largest VdS battery warehouses, and a sister company (Wamtechnik) among Europe’s top pack manufacturers, Battery-Kutter delivers from cell selection to finished packs—at scale.

What Battery-Kutter Delivers for BTM

-

Custom packs with application-specific BMS: temperature sensing on cells/modules, thermal limits, cell balancing, load control, and data logging (SoC, temperature, cycle count) via SMBus/I²C/CAN—enabling thermal monitoring and protection at pack level.

-

Thermal-aware engineering: pack design, sensor placement, harnessing, and interface to the vehicle or system BTMS to keep Li-ion packs in the ~15–35 °C sweet spot; options across chemistries (e.g., LFP via LiBrick and lead-acid families).

-

Safety & compliance built in: OEM-grade processes, VdS/UPS standards support, traceable QA, and protective functions that mitigate overheating, uneven cell temps, and thermal stress.

-

Supply, service, and scale: five German warehouse locations for high availability, pre-shipment Topcharging (up to 3,500 batteries/day), and rapid NPI through Wamtechnik’s engineering teams (~60 engineers).

Where It Fits

UPS/Energy storage, emergency lighting, telecoms, intralogistics & forklifts, light EVs, medical, security, wind/solar—from standard lead-acid to custom LFP packs.

Why It Matters

By embedding temperature monitoring and control in the BMS and aligning pack design with the host BTMS, Battery-Kutter helps customers stabilize pack temperatures, extend service life, improve safety, and reduce downtime—without over-engineering cooling hardware.

Dassault Systèmes

Multiscale Digital Twins for Battery Thermal Management

Dassault Systèmes delivers an end-to-end toolchain on the 3DEXPERIENCE® platform to design, simulate, and optimize battery thermal behavior—from chemistry → cell → module → pack → full vehicle.

What Dassault Systèmes Delivers for BTM

-

Unified platform (3DEXPERIENCE®): model-based, collaborative workflows linking requirements, CAD, simulation, controls, and data—so thermal, electrical, and mechanical teams iterate together.

-

CFD & CHT for packs and vehicles: PowerFLOW® with PowerTHERM® / PowerCOOL® predicts surface temperatures, heat flux, flow distribution, and hot spots; evaluates cold plates, manifolds, vents, and under-hood/under-floor airflow.

-

System-level (1D) battery modeling: CATIA Systems Engineering battery libraries capture coupled electrical–thermal behavior for cells/modules/packs and co-simulate with HVAC and vehicle duty cycles.

-

Cell/module / pack physics (3D): SIMULIA analyzes mechanical, thermal, diffusion, and electrical effects to optimize cooling channel topology, compression, and abuse/propagation scenarios (incl. thermal runaway).

-

Materials & aging: BIOVIA chemistry modeling to select and formulate materials for performance, safety, and cost—informing degradation-aware thermal strategies.

Use Cases & Workflows

-

Fast-charge & high-load optimization: keep cells within safe limits while reducing charge time.

-

Thermal protection & propagation studies: design barriers/vents and validate mitigation.

-

Cooling airflow & duty cycles: optimize heat-exchanger layouts, fans/shrouds; evaluate key-off/soak, hot/cold climates, and cabin comfort trade-offs with range/noise/drag.

Dassault Systèmes provides a multiphysics, multiscale digital twin that lets teams solve battery thermal challenges early—delivering safer packs, faster charging, and higher efficiency at vehicle scale.

Diabatix

AI-Generative Design for High-Performance Battery Cooling

Diabatix brings AI and generative design to battery thermal management. Its ColdStream SaaS platform automatically explores thousands of cooling concepts—then simulates, ranks, and refines them—so teams can deliver lighter, cheaper, and safer EV/BESS thermal hardware in a fraction of the usual time.

What Diabatix Delivers for BTM

-

AI-powered exploration: topology/generative design creates bespoke cold plates, flow fields, and manifolds that minimize thermal resistance, cut pressure drop, and improve temperature uniformity.

-

Simulation-first workflow: instant CFD-level evaluation of each candidate with multi-objective optimization (cooling performance, ΔT uniformity, Δp, mass, cost).

-

Manufacturing-aware outputs: designs tailored for plate stamping, roll-bonding, milling, or 3D printing, ready for downstream CAD/CAE and supplier handoff.

-

System context: cooling designs sized for fast-charge duty cycles and high energy-density packs, helping suppress hotspots that can precipitate thermal runaway.

Proof Points & Applications

-

Reported gains versus conventional designs: ~25% lower thermal resistance, ~15% better uniformity, ~50% lower pressure drop, and up to ~40% mass reduction in cooling components.

-

Use cases span EV battery packs, e-motors, power electronics, and home/industrial storage (e.g., work with MyGrid).

Outcomes for Programs

-

Faster development: rapid, automated iterations shrink concept-to-design timelines.

-

Performance & safety: tighter temperature control supports fast charging, reduces aging drivers, and helps mitigate propagation risks.

-

Cost & sustainability: lighter, lower-pressure-drop designs reduce materials, pump power, and BOM.